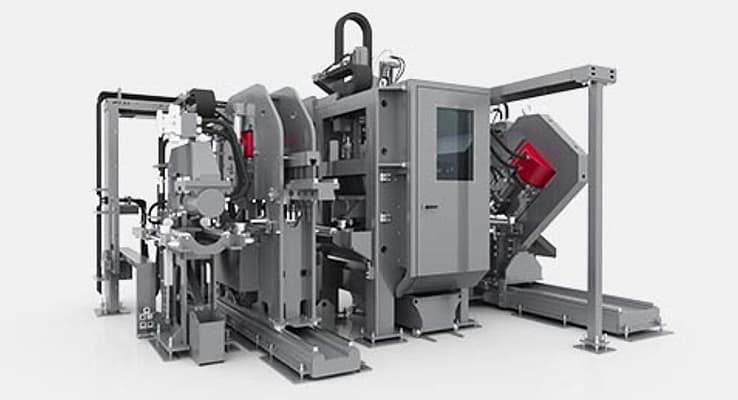

Beam Layout Welding Unit

This option comes with a platform equipped with rail guards. There are also stairs that allow for easy access. The platform is used to store flux wire and provides space for the operator's ability to load and unload flux hoppers as well change wire drums or reels. You can improve the speed, productivity, and accuracy of your Beam Laidout Welding with auxiliary equipment like the Flange Tilting Device from PHI and the Beam Turning Device.

.jpg)